From ThinkPad to Yoga, the look and feel of Lenovo laptops have always been in flux. But what has been maintained, according to Lenovo, is a longstanding ethos of making the highest quality products with the least environmental impact.

That might sound fairly vanilla to you, but Lenovo really has been leading the charge to more eco-friendly tech over the past decade. The company moved to 100% recycled packaging way back in 2008 and has even gone to experiment with bamboo and sugarcane-based materials.

But Lenovo has new tricks up its sleeve. I was invited to visit the Lenovo headquarters in Raleigh to see the innovations firsthand and to see if there was any validity to the company’s confident claims about its industry-leading sustainability initiatives.

Packaging and materials

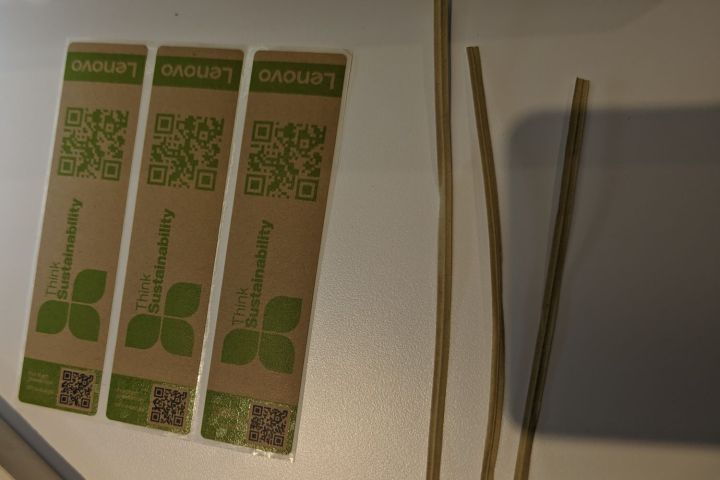

Similar to many other laptop manufacturers, Lenovo has delved into its sustainability efforts very easily through its packaging. The eco-friendly tan Lenovo box is as synonymous with the brand as its red logo. Made of bamboo and sugarcane fiber, the boxes are easily recyclable and compostable. The company said it chose these materials because of their fast growth and easy accessibility. To look inside a Lenovo box further shows a meticulous effort to shy away from materials that are harmful to the planet.

Devices, and even accessories such as USB-C to HDMI and RJ45 cables, are also housed in linen bags made of bamboo and sugarcane fiber instead of plastic. Cardboard bumpers that keep products in place are made of the same materials. Beyond that, Lenovo is making efforts to make its entire packaging plastic-free, putting detail into changing twist ties from plastic-coated to paper-coated and using paper-based security labels as opposed to plastic. Text on the packaging is also printed with water-based ink. Such efforts have already been implemented into product lines such as the ThinkPad series.

Lenovo says the lessons it learned from its packaging are starting to be transferred to sourcing materials across many of its product lines. Using not only recycled plastics, fabrics, and foraged aluminum but also introducing new materials from eco-friendly sources as well as from sources unique to the technology space. The company noted its new Z series devices are made of 75% foraged aluminum which is energy- and consumption-saving, while its Yoga series devices are made of 50% recycled fabric, and its Tab P12 Pro first Android tablet in the world made of 100% recycled aluminum.

“This year in our look into trends around sustainability we’re seeing a little bit of a shift around micro-trends from materials only to materials, processes, to manufacturing, everything,” Lenovo PCSD Senior Design Manager Strategic Design and Innovation, Ali Elliott said. “We’re seeing a lot of new natural materials. We’re also seeing a huge jump for design that includes apparent sustainability from the jump.”

The company has invested in a number of new sources that are not only eco-friendly but aesthetically pleasing. Accessories for the ThinkPad Z series include cases made of vegan leather sourced from cactus plants. The ThinkPad X1 series, meanwhile, is a longstanding laptop line that is made with recycled nylon.

The covers for laptops in the Legion gaming series are made of the fuselage or the carbon fiber innards of airplanes. Using reclaimed waste material sourced from Boeing, the bits are hammered down into patterns that ultimately make the covers unique to each model. Similarly, the cover of the ThinkPad Z13 was created from woven stalks of flaxseed plants and bonded in a biodegradable resin. The stalks are also a waste product, and in the weaving process make a unique design for the cover of each ThinkPad Z13 model. Lenovo notes it doesn’t have any exclusivity to using flaxseed stalks as a material, it is simply first to market. The ThinkPad Z13 also features a 75% recycled aluminum frame and it ships in one of the 100% plastic-free boxes.

“When we’re looking at a product, we want to make sure we’re introducing sustainable materials into as many components of that as we possibly can,” Elliott said.

Futuristic design

As Lenovo makes way for future endeavors, it is taking into consideration the wants and needs of its customers. Among those talks are long-standing discussions about customization, modulation, and how much consumers want to be involved in the repair of their devices. Lenovo notes these conversations will shape the look and feel of devices for years and decades to come.

“Customers vary. There is a wide spectrum of what customers in commercial or consumer spaces are wanting. What kinds of changes they are sensitive to and when it comes to repair itself, with a spectrum of abilities and awareness about that issue,” Lenovo Group Operations Distinguished Designer and Head of Next UX User & Customer Experience, Aaron Stewart said.

Having done a consumer study of repair preferences, Lenovo learned that repairability was important to most consumers when considering a laptop for purchase. Delving deeper into these thoughts, the company found 60% preferred repairs to be done by manufacturers, while 20% preferred some sort of DIY option.

The research has led Lenovo to consider several repurpose and repair options that could benefit consumers that might be a little more hands-on. Called Project Aurora, it remains in the concept phase, but is Lenovo exploring methods of execution.

“We looked at how we could arrange components in devices. We’re studying the effects of building differently. It’s about assessing approaches to repair and upgrade. We don’t have the final answer on this, but we’re looking at which components need to be repaired the most and which ones should be more accessible,” Stewart said.

Lenovo said it sees such a project rolling out initially for enterprise customers. Other options under the research entail allowing certain standardized parts of products to be refashioned and upcycled into a new product at the end of life. For example, a functional display on a laptop could be removed and repurposed as a smart display. Lenovo also envisions devices with various detachable parts that customers can send back to the manufacturer to have replacement parts shipped back for them to reattach manually. Questions the company is still grappling with are how can these efforts be not only feasible but sustainable at the same time.

Water cooling for sustainability

Outside of Lenovo’s hardware and material efforts, the company has also developed technology that benefits sustainability on a massive solution-based scale. Its Neptune liquid cooling system has been implemented into supercomputers in data centers across the world as an option to offset the rapidly increasing power demands on components such as GPUs, CPUs, memory, and network adapters, but also the power that it takes to keep systems cool.

Standard data centers are typically cooled by air, with a cold aisle in front of the servers and a hot aisle in the back. Air is cycled down through racks in an air conditioning system to be cooled and up again when it’s warm to repeat the process.

“Anywhere between 30% and 40% of any server is used to pull the system. It’s just used to run the fans. It’s not calculating data. It’s not moving data. It’s not storing data. It’s just moving air,” Lenovo Infrastructure Solutions Group Director of Marketing High Performance and Artificial Intelligence, Patrick Moakley said.

With components expected to quickly increase in specs and power capacity in the coming years, any methods for power reduction and efficiency are welcome by organizations utilizing supercomputers.

The industry is expected to produce CPUs at 500 watts and GPUs at 700 watts. Keeping in mind that smaller components, including memory and network adapters also consume power, companies might have to invest in computers that consume 1,000 watts per system, Moakley added.

The Neptune liquid cooling system works as a dry cooler, similar to an automotive radiator with liquid flowing through the coils inside a supercomputer, which interacts with the ambient air to keep the water and the system cool. This method automatically erases the 30% and 40% power expenditure it takes to cool systems when data processing.

“For those dry coolers to operate, you just need a temperature difference between the water and the ambient air outside. So when the air is cooler than the water exiting, then the act of blowing air over those coils, the heat will naturally be dissipated from the water and go to the universe to then be cool. And then return the water, more importantly back to the end that water temperature that we require for these services,” Lenovo Thermal Engineer, Scott Holland said.

This is where Lenovo’s liquid cooling system steps in as a two-fold benefit of helping organizations maintain or even increase their performance with water while having the source be an efficient byproduct that can be used elsewhere.

“You get up to a point where you’ve got cool water coming in. You discharge warm water going out. The benefit to having warm water coming out of the system as opposed to warm air is it’s really, really difficult to contain warm air. Warm water is contained. I can do something with it. I can send that to some other place within my campus,” Moakley said.

Lenovo has collaborated with a multitude of organizations globally on water recycling such as heating pools and heating buildings. Its partners include Harvard University, Yale University, Max Planck Institutes, Barcelona Supercomputing Center, National Computational Infrastructure, and the Indian Space Research Organization, among others.

With data center power having almost quadrupled in the last decade and expected to quadruple again by the end of the decade, it is likely even more organizations will soon be interested in alternative cooling methods.

A long way to go

Companies like Lenovo might not be able to abandon their current way of manufacturing laptops, but there’s no doubt in my mind — the issues of sustainability are no longer an afterthought. Processes are being reconsidered, experiments are being undertaken, and products are being reimagined. We’re a long way from the sustainability revolution, but the gears have begun to turn.

Editors’ Recommendations